QuantumScape opens pilot production line for solid-state EV batteries

We have been waiting for a "holy grail" of battery technology that makes charging as fast as filling a gas tank for the better part of this century. QuantumScape, a battery company based in California, took a massive step toward making that a reality. This week, the company officially opened its Eagle Line in San Jose. It is a highly automated pilot production line designed to prove that the next generation of EV batteries can be built at a massive scale.

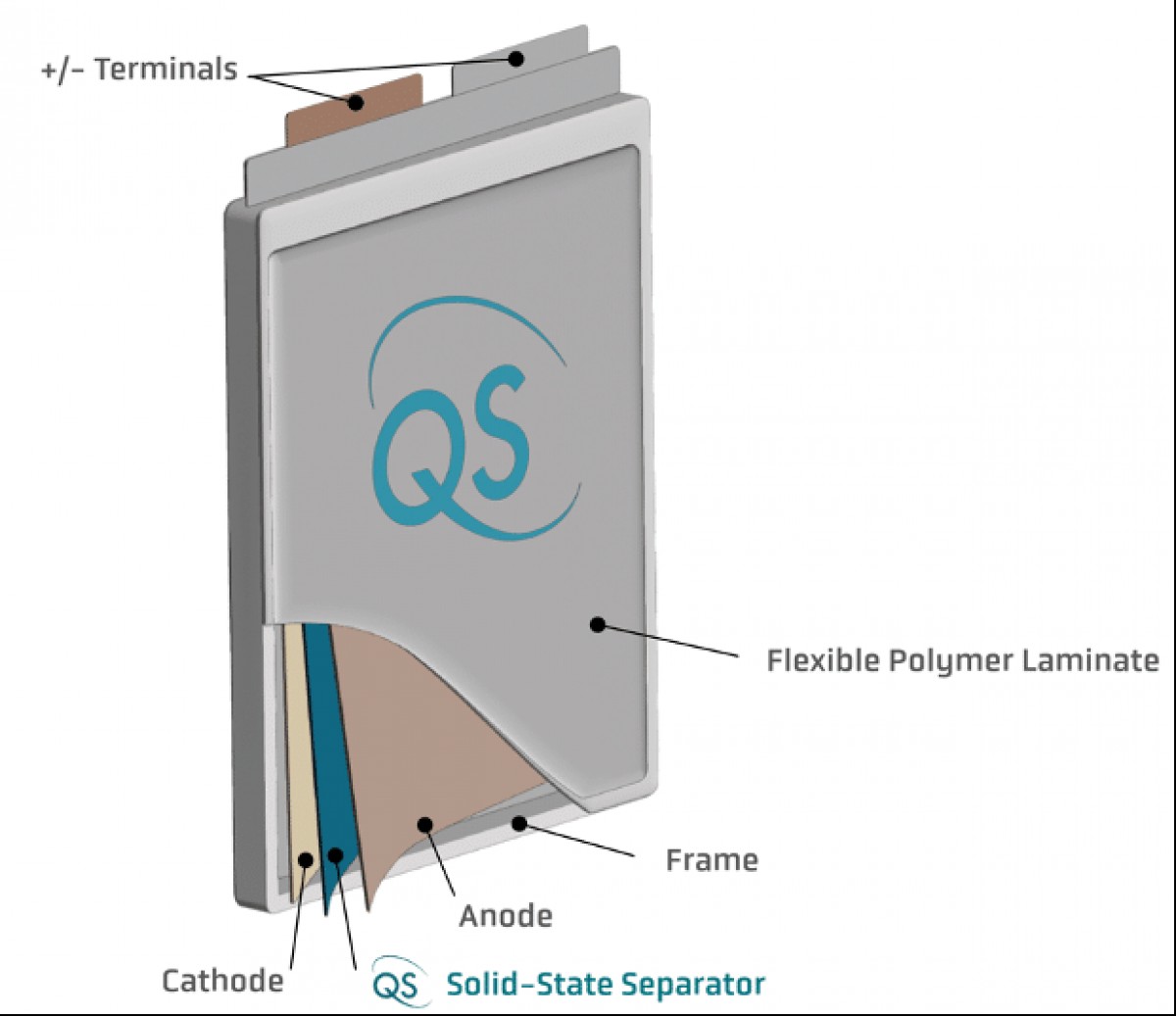

The new facility revolves around a process the company calls Cobra. This special manufacturing method builds a proprietary ceramic separator. In a standard battery, the separator keeps the positive and negative sides apart while letting energy flow through a liquid. QuantumScape's version is solid, which allows the company to use a lithium-metal anode. This change is a big deal for electric cars because it removes the liquid and the bulky graphite found in today's batteries.

QuantumScape team at the opening of the Eagle production line- source: QuantumScape

QuantumScape team at the opening of the Eagle production line- source: QuantumScape

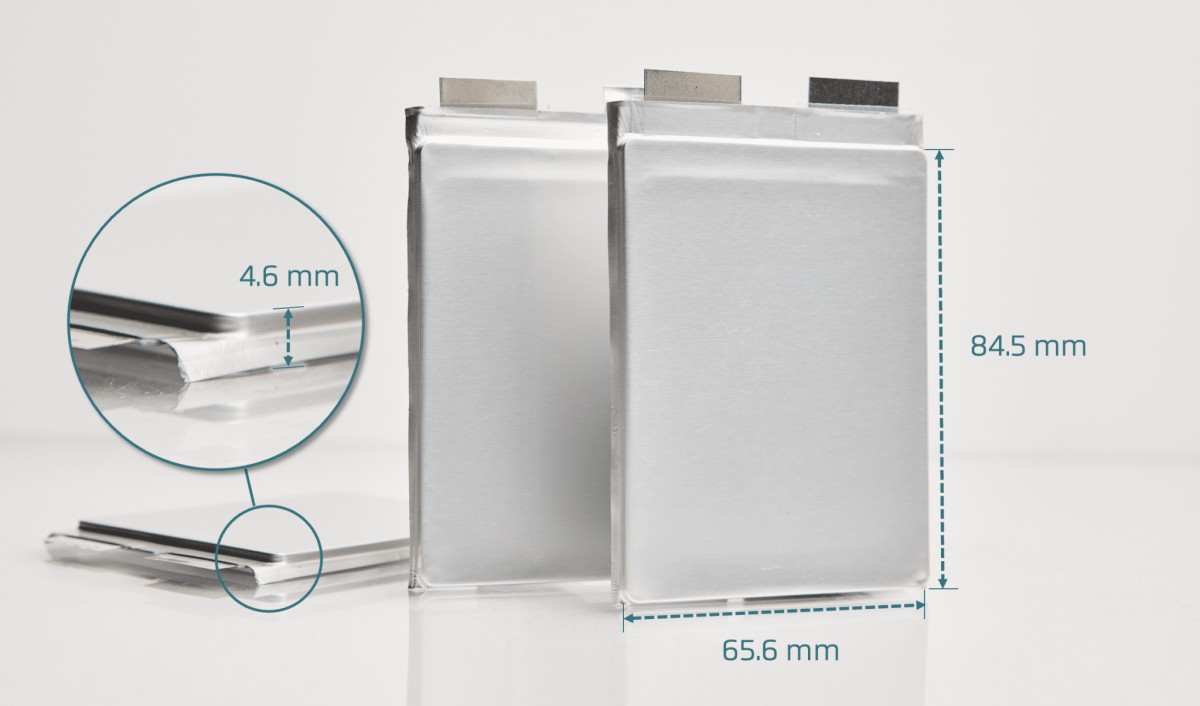

The solid-state batteries coming off the Eagle Line, known as QSE-5 cells, offer performance numbers that make current technology look a bit dusty. These cells have an energy density of 844 Wh/L (301 Wh/kg) - they can store much more power (double the current standards in some cases) in the same amount of space. This could boost the range of a typical electric car from 249 miles to 311 miles without making the battery pack any larger or heavier.

Charging speed is another area where these new batteries will shine. The new cells can charge from 10% to 80% in less than 15 minutes, and after 1,000 charging cycles, they keep 95% of their original capacity. Because the separator is made of ceramic rather than flammable plastic and liquid, the batteries are also much safer. They can handle higher temperatures and are less likely to catch fire if something goes wrong.

Construction of the solid-state battery cell - source: QuantumScape

Construction of the solid-state battery cell - source: QuantumScape

The Eagle Line is designed to be a "blueprint." QuantumScape plans to show other companies how to build these batteries so they can be produced in giant factories. At the opening event, leaders from car companies and the government gathered to see the machines in action. The Eagle Line uses high-tech automation to ensure every battery is made with perfect quality. The new batteries are more expensive to make than standard ones at the moment. Some industry estimates for early solid-state tech range from $400 to $800 per kWh, but the goal of the Eagle Line is to bring those costs down.

By using the Cobra process, QuantumScape has managed to speed up production quite a bit, and the company isn't just keeping this tech for itself. They plan to use a licensing model that will let other manufacturers use their "blueprint" to build batteries at a gigawatt-hour scale.

Dimensions of the QSE-5 battery cell - source: QuantumScape

Dimensions of the QSE-5 battery cell - source: QuantumScape

For the average person, this news means the "range anxiety" often tied to EVs might finally disappear. If a car can drive further and charge in minutes, the biggest hurdles to owning an electric vehicle are gone. The QSE-5 cells are already being sent to partners like Volkswagen and Ducati for testing.

The Eagle Line will also serve as a test lab for even better versions of the technology. As the machines in San Jose ramp up, the data they collect will help refine the manufacturing process. QuantumScape says their cells can last for over 300,000 miles of driving while still holding most of their original charge.

Related

Reader comments

- Anonymous

yes but they are more prone to catching fire, SSB are safer and use less rare earth metals

- 09 Feb 2026

- U@m

- Anonymous

This battery is even worse than silicon-carbon batteries found in Xiaomi phones; those at least have over 900wh/l and probably very high wh/kg as well.

- 08 Feb 2026

- 35Z

- Anonymous

Semi SSB nio used was 150Kwh.40kwh Semi SSB MG4 is 180wh/kg 2026. So 301 wh/kg is quiet revolutionary considering its first gen and 1000 wh/kg has already been demonstrated and LFP cant go that high

- 07 Feb 2026

- U@m