Tesla's new factory promises cheaper batteries for more affordable EVs

In the high desert of Nevada, a stone's throw from its original Gigafactory, Tesla is putting the finishing touches on a new facility that could quietly reshape the future of electric cars and green energy in North America.

Tesla's first North American plant dedicated to producing Lithium Iron Phosphate (LFP) batteries is a sign of a major strategic shift for the electric vehicle pioneer. The implications are huge, pointing toward a future with more resilient energy grids and, most importantly for many consumers, the potential for more affordable electric cars.

Nearing completion of our first LFP cell manufacturing factory in North America pic.twitter.com/OLNRWajz4l

— Tesla (@Tesla) June 28, 2025

The dominant battery chemistry in the electric vehicle world until now, at least in the US, has been nickel-based, like Nickel Cobalt Aluminum (NCA) and Nickel Cobalt Manganese (NCM). These batteries pack a lot of energy into a small space, giving EVs the long range that drivers want. The downside is that they rely on expensive and controversially sourced materials, namely cobalt. Tesla, like many other automakers, has been looking for a better, cheaper, and more stable alternative. They found it in LFP.

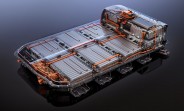

LFP batteries are the workhorses of the battery world. What they lack in energy density compared to their nickel-based cousins, they make up for in other critical areas. They are significantly cheaper to produce because they use abundant and inexpensive iron instead of cobalt and nickel. They are also remarkably stable, meaning they have a much lower risk of overheating and fire. They offer a longer lifespan and are capable of handling thousands more charge and discharge cycles. This makes them an ideal choice for stationary energy storage, where size and weight are less of a concern than cost and longevity.

This is where the immediate impact of the new Nevada factory will be felt. The primary mission of this facility is to manufacture LFP battery cells for Tesla's growing energy division. These cells will power the Megapack, a massive battery system designed for utility companies to stabilize electrical grids, and the Powerwall, a home battery system that allows homeowners to store solar energy or backup power. Until now, Tesla has been importing these crucial LFP cells from suppliers like CATL in China.

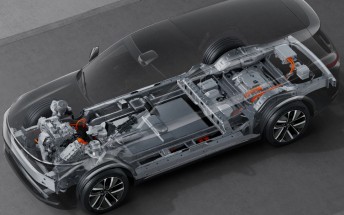

The real excitement for future EV buyers lies in what this factory means for Tesla's vehicle lineup. While Tesla already uses LFP batteries in its standard-range Model 3 and Model Y vehicles in markets like Europe and China, they have been largely absent from the North American scene due to high import tariffs. A domestic supply of LFP cells changes the entire equation.

This could pave the way for the reintroduction of LFP-powered vehicles to the American market, possibly as early as 2027. An American-made LFP battery pack could lead to a less expensive base Model 3 or Model Y, dropping the entry price for a new Tesla. Beyond that, it's a key ingredient for Tesla's long-promised next-generation vehicle, often dubbed the "$25,000 car."

While that price point remains speculative, cost-effective LFP batteries are essential to making a truly mass-market EV a reality. For consumers, this means a lower sticker price and the practical benefit of being able to regularly charge their car to 100% without significant long-term battery degradation, a practice generally discouraged for nickel-based batteries.

Related

Reader comments

Nothing yet. Be the first to comment.