UK’s electric car future gets a second life with recycled batteries

Electric cars might be seen as the clean, green solution to personal transportation, but there's no getting away from the fact that every EV has a big, heavy secret: its battery. Mining for new materials like lithium, cobalt, and nickel is energy-intensive and heavy on the environment. It also raises the uncomfortable question of what to do with millions of batteries once they can no longer power a car. Now, a collaboration in the United Kingdom is offering a promising answer.

Automaker Jaguar Land Rover (JLR) has teamed up with clean technology group Altilium to create the UK's first electric car battery cells built with recycled materials. Unveiled at the recent Cenex Expo 2025, these cells are a huge step toward creating a self-sustaining battery supply chain within the country.

Instead of relying solely on newly mined metals shipped from across the globe, this project proves that the valuable materials in old batteries can be recovered and given a new life in high-performance electric cars.

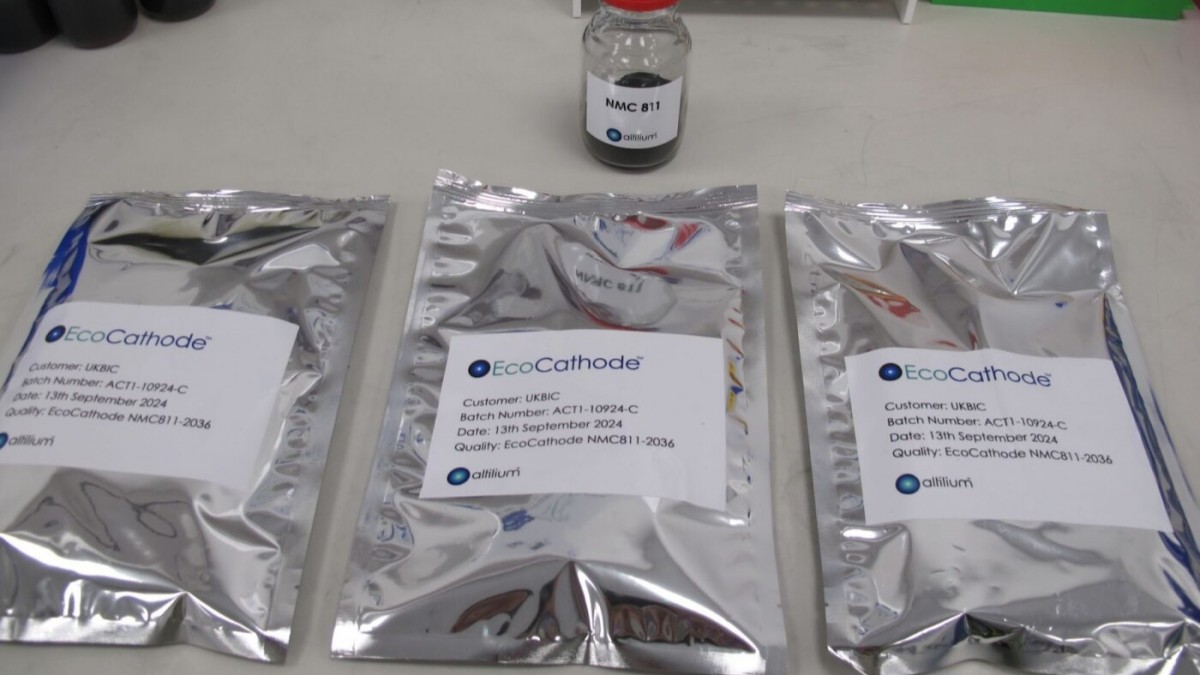

The technology behind this breakthrough is Altilium's proprietary EcoCathode™ process. This advanced recycling method can take end-of-life EV batteries and efficiently extract the critical elements inside. The company reports a recovery rate of over 95% for cathode metals and more than 99% for graphite, the primary material in the anode.

These recovered materials are then processed into fresh Cathode Active Material (CAM), the key ingredient that determines a battery's performance. The demonstration cells are a specific type known as NMC 811 multilayer pouch cells, a modern chemistry used in many current EVs.

The real test, of course, is whether these recycled batteries are as good as new ones. According to initial testing, the answer is yes. The performance of the recycled cells is reportedly comparable to that of cells made with conventional primary materials.

To prove the concept, the cells are now undergoing extensive and rigorous validation at Jaguar's advanced battery testing facilities. At the Cenex Expo, the companies even showed a virtual reality model of how these new cells would fit into a Jaguar I-PACE battery pack.

The environmental benefits are substantial. An independent Life Cycle Assessment confirmed that using Altilium's recycled CAM reduces the climate impact by 32% compared to using all-new materials. The process also leads to a 30% reduction in particulate matter formation, a 58% drop in freshwater toxicity, and a 38% decrease in the depletion of metal and mineral resources.

The good public relations aside, this is a strategic development to prepare for the future. The European Union set targets for the use of recycled content in new EV batteries, with minimum levels required by 2036. The recycled material concentration in the JLR and Altilium demonstration cells - containing 26% cobalt, 12% lithium, and 15% recycled nickel - already meets these future mandates.

And let's not forget that by creating a domestic, circular economy for batteries, the UK can reduce its dependence on volatile international supply chains. For consumers, this innovation paves the way for electric cars that are not only cleaner to drive but also cleaner to produce. Cheaper? Maybe not just yet.

Related

Reader comments

Nothing yet. Be the first to comment.